Electroforming (plating) at Quality Record Pressings

The secret to success in high-quality lacquer plating — a crucial step in the LP manufacturing process — is attention to detail. Knowing the condition of the chemicals in the plating tank, making adjustments through filtration and chemical additions, and staying on top of temperature variations.

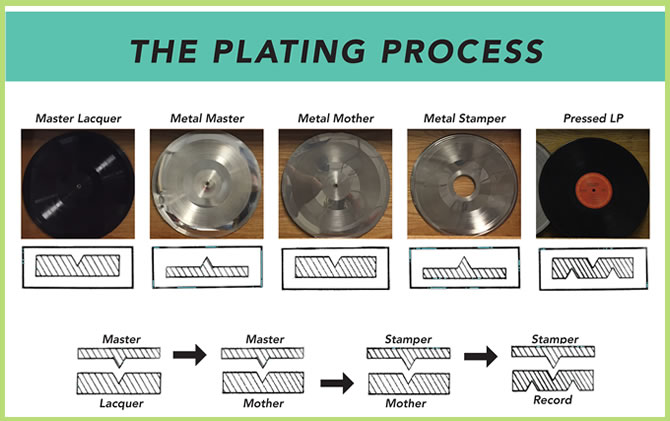

In a nutshell, the plating process includes first spraying a lacquer with silver nitrate to make it electrically conductive. From there, a nickel plate is added, creating a master. The master is a negative of the lacquer, meaning rather than grooves there are raised ridges. From there, a mother is created, which is a positive with grooves. The mother then produces stampers, typically at least five per mother. The stamper is what is set in the press to act as the mold that creates vinyl records. Each stamper should yield about 750 to 1,000 records depending on a number of variables.

Having an in-plant plating department at QRP is a tremendous advantage. That way, parts can be made as they are needed. Each stamper has a taper and weight specially designed to match our presses.

Just as you can’t have an excellent vinyl release without a great recording, great mastering, a superior grade and weight of vinyl and an error-free pressing, you also can’t produce an excellent LP without great plating. It’s likely one of the more invisible links in the chain to most end consumers. Just as you can’t have an excellent vinyl release without a great recording, great mastering, a superior grade and weight of vinyl and an error-free pressing, you also can’t produce an excellent LP without great plating. It’s likely one of the more invisible links in the chain to most end consumers.

Yet it affects everything from something as basic as pre-echo and high-end loss all the way through to record profile and warping. And stampers that aren’t evenly matched weight-wise and profile-wise can create non-fill or stitching problems in the LPs being pressed.

One of the key elements to correct plating is respecting the fact that a lacquer is a soft material that, once it’s been cut (mastered), is always changing. If that lacquer is exposed to extremes – either in the environment or in the plating tank – it will result in pre-echo, and you can actually lose some of the high-end frequencies. It’s why it’s important that lacquers arriving at QRP go into the tank and begin the plating process within 24 hours of their arrival at our plant.

The goal, as always, is to obtain the highest quality LPs possible. Not only producing exceptional sound quality, but total product consistency throughout the entire press run.

|